Operation Process of Milking Machine

Author:小编

UpdateTime:2024-10-22

Click:

A milking machine is an automated device used for efficiently and hygienically extracting milk from dairy cows. Its operation process typically includes the following steps:

Preparation Stage

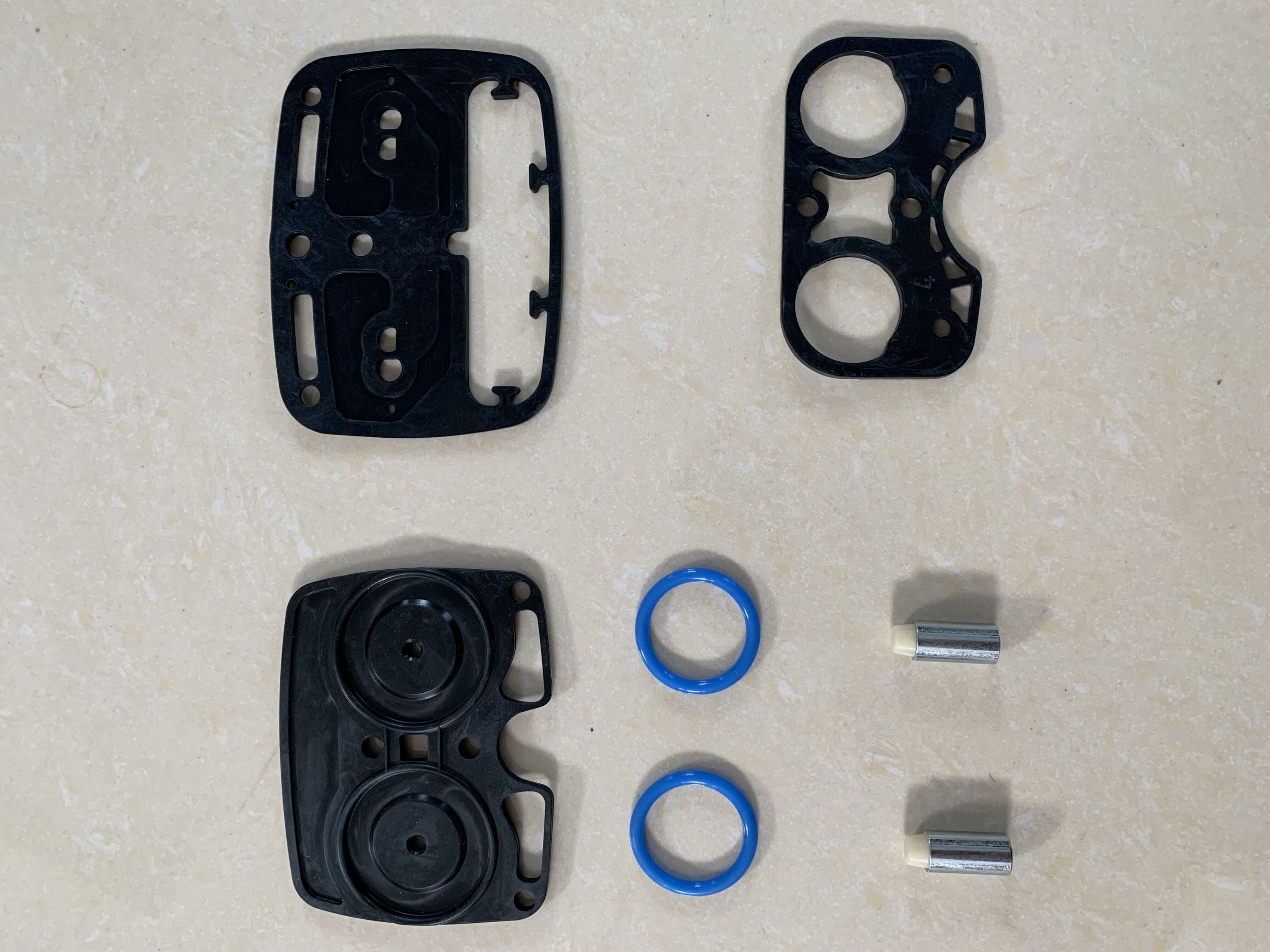

- Cleaning and Disinfection: Before starting the milking process, it is essential to thoroughly clean and disinfect the milking equipment, including teat cups, pipes, pulsators, etc.

- Cattle Preparation: Guide the cows to the milking stalls and clean and disinfect the teats to remove surface dirt and bacteria.

- Pre-stimulation: Gently massage the teats by hand to stimulate the cow's milk letdown reflex, encouraging milk to flow into the udder.

Connecting the Milking Equipment

- Installing Teat Cups: Attach the four teat cups to the cow's four teats. The teat cups are connected to the pulsator and vacuum pump via hoses.

- Starting the Vacuum System: Turn on the vacuum pump to generate a stable vacuum pressure, typically between 40-50 kPa.

Milking Process

- Pulsator Operation: The pulsator works by creating periodic changes in vacuum pressure, simulating the natural sucking process. Each pulsation cycle consists of two phases:

- Milking Phase: The vacuum pressure is high (about 40-50 kPa), and milk is drawn from the teats.

- Resting Phase: The vacuum pressure is low (about 0-10 kPa), allowing the teats to rest briefly, which helps prevent teat damage and maintain blood flow to the teats.

- Milk Collection: The milk extracted from the teats is transported through the pipes to the milk collection tank. The collection tank usually has filters and cooling devices to ensure the cleanliness and freshness of the milk.

- Monitoring and Control: Modern milking machines are typically equipped with sensors and control systems that monitor parameters such as milk flow rate and vacuum pressure, ensuring the smooth operation of the milking process.

- Pulsator Operation: The pulsator works by creating periodic changes in vacuum pressure, simulating the natural sucking process. Each pulsation cycle consists of two phases:

Completion Stage

- Automatic Cup Removal: When the milk flow rate drops to a preset minimum value, the milking machine automatically shuts off the vacuum pump, and the teat cups detach from the teats.

- Teat Disinfection: Disinfect the teats again with a disinfectant solution to prevent bacterial infection.

- Equipment Cleaning: Remove the teat cups and pipes and thoroughly clean and disinfect them, preparing for the next use.

Post-processing

- Milk Storage: Store the collected milk in a refrigerated tank to keep it at a low temperature and prevent bacterial growth.

- Transportation: Regularly transport the milk from the refrigerated tank to the processing plant for further processing and packaging.

Maintenance and Care

- Daily Inspection: Check all components of the milking equipment daily to ensure there is no damage or blockage.

- Periodic Maintenance: Regularly replace worn parts, such as milk tubes and teat cup liners, to ensure the proper functioning of the equipment.

- Record Keeping and Monitoring: Record the time of each milking session, the amount of milk, and the equipment's operational status. Conduct regular data analysis to optimize the milking process.

Summary

The operation process of a milking machine includes the preparation stage, connecting the milking equipment, the milking process, the completion stage, and post-processing. Through automated and standardized processes, milking machines not only improve milking efficiency but also ensure the hygiene and quality of the milk. Regular maintenance and care are crucial for ensuring the long-term stable operation of the equipment.